Traditional reliance on soda ash (sodium carbonate) and alumina faces growing challenges: stringent environmental regulations, severe price volatility, and critical occupational health risks. Sodium feldspar, a natural mineral, is emerging as the pivotal solution for green transformation.

The Traditional Raw Material Dilemma: Costs, Risks & Pollution

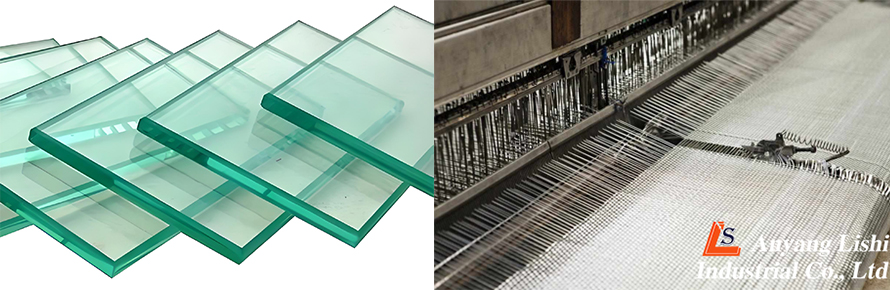

The foundation of glass production remains silica sand, soda ash, and limestone, often supplemented by alumina for performance. This system carries significant burdens:

?Soda Ash's Environmental Toll: Production is energy-intensive, releasing ~0.5-1 ton of CO? per ton of soda ash. It generates massive calcium chloride (CaCl?) wastewater and solid waste, posing contamination risks and high treatment costs. Its use in melting also releases CO?.

?Price Volatility & Supply Risk: Both soda ash and alumina prices are tied to volatile commodity futures. Production is dominated by a few large corporations, creating oligopolistic control and supply chain instability, making cost management difficult.

?Occupational Health Hazard: Many mineral raw materials contain free silica (SiO?) dust. Inhalation causes silicosis and other pneumoconioses, threatening worker health, increasing safety compliance costs, and exposing companies to legal liabilities.

Sodium Feldspar: Nature's Efficient Solution

Sodium feldspar (NaAlSi?O?) is a natural aluminosilicate mineral offering a dual advantage:

?High-Efficiency Fluxing Agent: Its alkali content (Na?O) acts as a powerful flux, breaking down silica's structure and lowering the melting temperature. This delivers:

?Significant Energy Savings: Reduced fuel consumption and lower CO? emissions.

?Reduced Soda Ash Dependency: Replaces 20-40% of soda ash, cutting costs and exposure to its price volatility and environmental impact.

?Improved Process Control: Optimizes melt viscosity, enhancing clarification, homogenization, and fiberglass quality consistency.

?Premium Alumina Source: It efficiently introduces alumina (Al?O?), crucial for enhancing glass performance:

?Increased Hardness & Strength: Boosts mechanical durability.

?Enhanced Chemical Resistance: Improves resistance to water, acids, and alkalis.

?Better Workability: Makes glass more suitable for pressing and other forming processes.

LSFerroalloy Sodium Feldspar: The Industry Benchmark

High Sodium (10.5±0.5%): Guarantees optimal fluxing power for maximum energy savings and soda ash reduction, ensuring process stability and consistent quality.

Exceptionally High Alumina: Provides ample Al?O? to meet stringent requirements for high-strength fiberglass, electronic glass, and other high-performance applications, enhancing durability and chemical resistance.

Free-Silica-Free (SiO?): Eliminates silicosis risk at the source. This drastically improves workplace safety, protects employee health, reduces safety investments, and mitigates legal risks.

Low-Temperature Fast-Firing: Superior reactivity promotes rapid melting and homogenization, shortening cycle times, boosting furnace efficiency, and maximizing energy-saving potential.

Natural & Eco-Friendly: As a pure mineral, it aligns with green policies. Replacing sodaash/alumina directly cuts CO? emissions, CaCl? wastewater, and solid waste, lowering environmental compliance costs.

Price Stability & Supply Security: Offers significantly lower price volatility compared to soda ash and alumina, providing cost predictability and supply chain resilience.

Conclusion

Facing environmental regulations, rising costs, supply chain uncertainty, and safety demands, LSFerroalloy sodium feldspar is the strategic imperative. Its core advantages – high sodium, high alumina, free-silica-free, low-temperature fast-firing – combined with the inherent benefits of a natural mineral (eco-compliance, price stability, safety) make it the ideal solution to replace traditional soda ash and alumina.